Deep Tech Dispatch | #21

Single atom computers | Acoustic force fields | Tabletop accelerators | Inflatable space stations | Manufacturing GTM | Pasta science and much more

🙋🏻♂️ A Short Preface

Fellow nerds and nerdines,

Apologies for the disruption in the upload schedule (again) - busy times, the end of year sprint is real! But I will make up for it next year with more regular content again and a few bangers that have been slow cooking in my brain over the last months. So be my guest, grab a coffee and get a christmas-y snack. You’ll hear from me early January again. See you soon and enjoy the festive season with family & friends (and maybe a little bit of DeepTech) - Felix.

This week’s dispatch contains the follow:

⚛️ Atomic switches for molecular electronic devices

🔊 Moving matter with sound waves - “invisible hands”

💥 Table top X-ray accelerators

✈️ Supersonic commercial flight makes progress

🛰️ Project Suncatcher

🌌 Inflatable space stations from China

☢️ Nuclear reactors underground

🧬 DNA data storage

🏭 Nailing Manufacturing Software GTM

🍝 Characterising the perfect pasta with particle accelerators

Reading time: 14 minutes.

🧑🏻🔬 Science & Research News

Atomic switches for molecular electronic devices

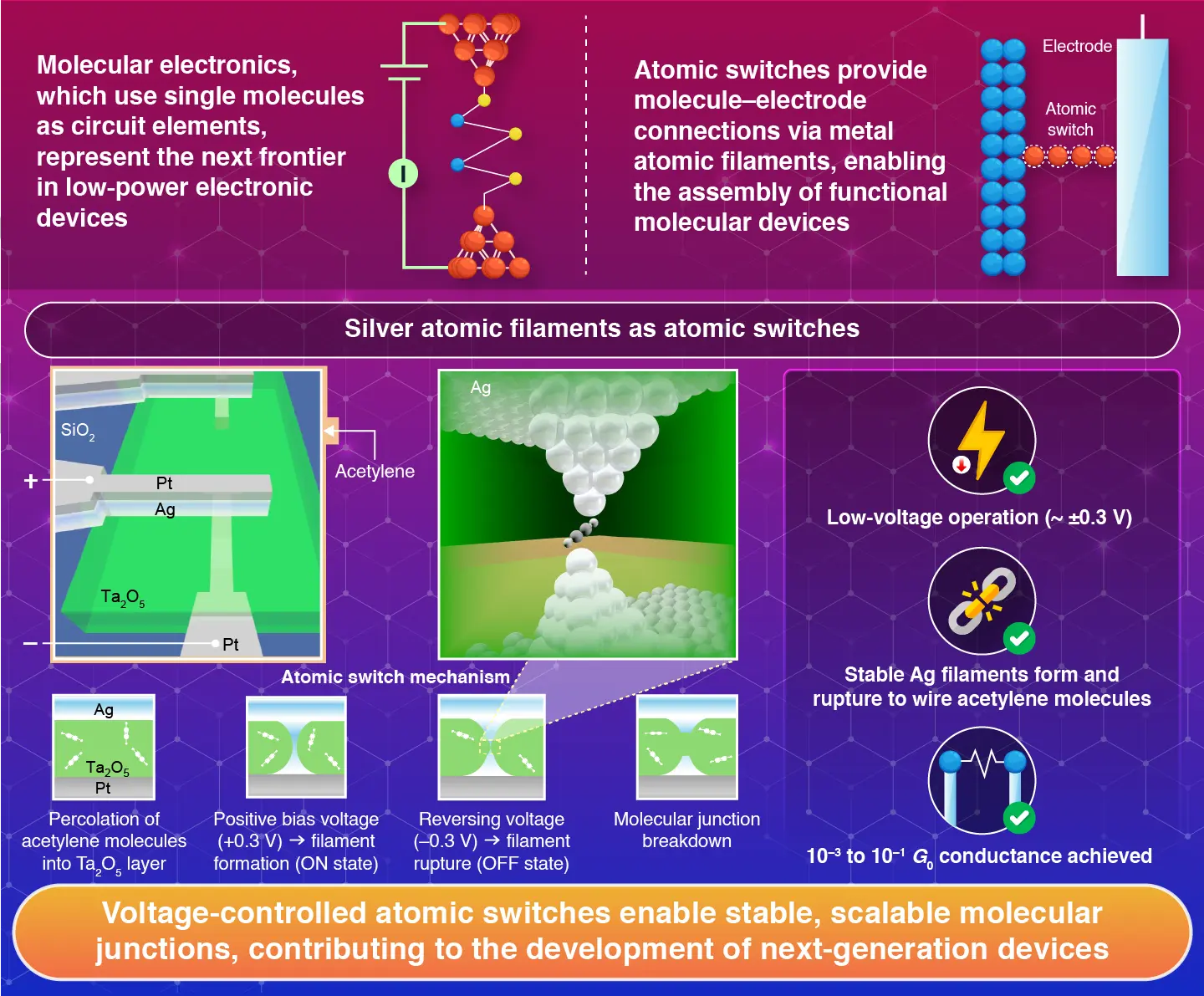

Researchers from the Institute of Science Tokyo have developed a breakthrough method for wiring single molecules into electronic circuits. More specifically they have created a stable electrical connection between molecules using switches made up of silver atoms. Pretty much transistors as you know them from computing that can represent logic by being switched on and off, just with single atoms.

Why does this matter? Theoretically - good start to something relevant I know - it makes sense to build computers (now also called ✨AI factories✨) out of single molecules. Because if you can make things smaller they usually become more efficient and you can put more of the same thing into the same volume. Practically - now the un-fun part begins - this is very very challenging. Assembling single atoms into a functional compute chip is at the moment impossible to scale up, as you need to physically move all these atoms to create the necessary structures. This doesn’t matter when you’re creating a single transistor to prove that it works, but matters a lot if you’re assembling billions to create a fully functional chip. Well, it is a first step!

So how does creating a transistor out of single atoms work? You take two electrodes separated by an insulating layer so that no electrons can flow. If a certain voltage is applied to them, the silver atoms floating around migrate to the electrodes closing the gap and creating a circuit, turning the switch “on” - electrons can flow. Reversing the voltage breaks this connection off as the silver dissolves, turning the switch “off”. Atomic computing. Cool, but for a far away post-silicon future. You can find the article here and the paper here.

Moving matter with sound waves - “invisible hands”

Researchers at Virginia Tech have developed a way to use sound waves to precisely move (small amounts of) matter. If you’ve been to concerts “moving matter with sound” shouldn’t be that surprising - in those settings you can really feel the powerful sound physically applying pressure to your body. The trick with sound though is to precisely direct it that you can do proper controlled and intended physical manipulations.

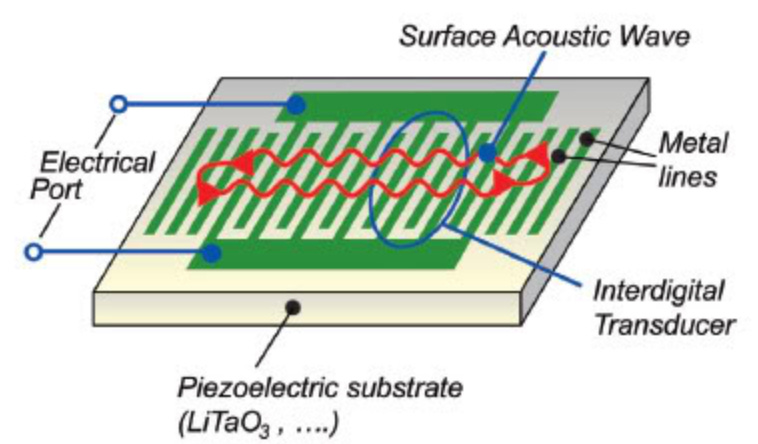

Concretely, the researchers have created a small chip with a delicate design of electrodes that generate the sound in a way that very precise operations are possible. To give more context here, sound waves can be created electronically on chips with a device called interdigital transducer. These are interlocked, comb-like metal electrodes on a piezoelectric material that convert electrical signals into mechanical oscillation resulting in acoustic waves and vice-versa, leveraging the piezoelectric effect: an applied alternating current voltage creates alternating electric fields between the fingers (electrodes), causing periodic expansion/contraction generating sound waves.

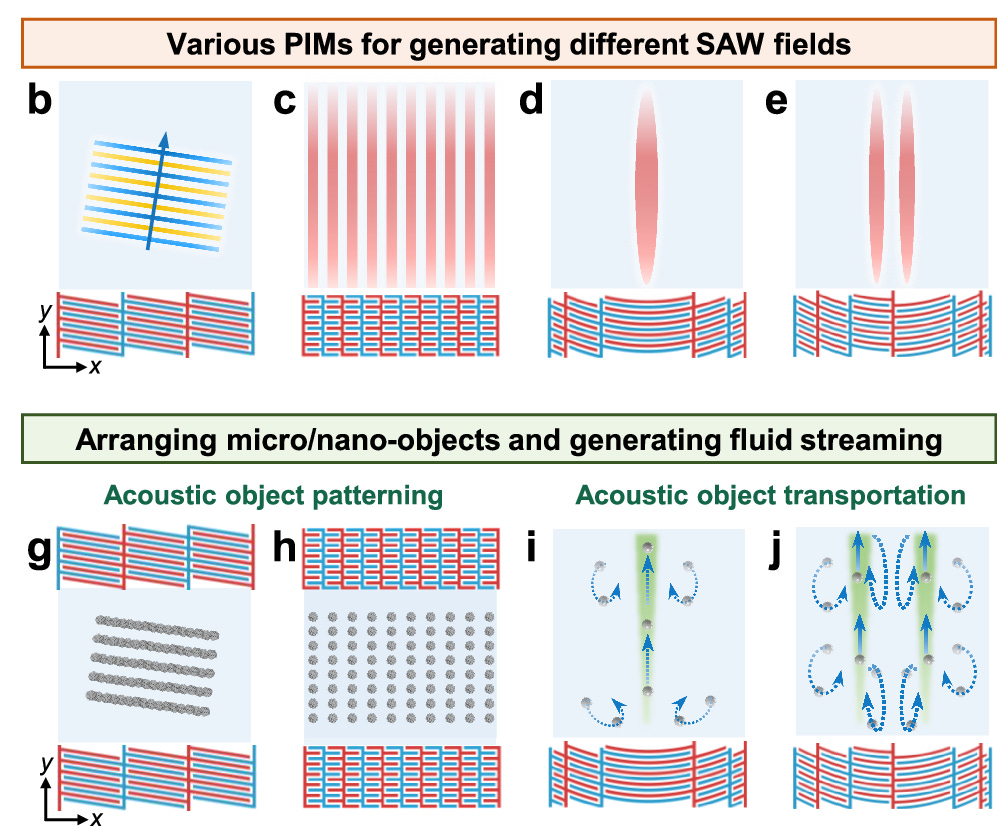

In this case, the researchers found that if you arrange these electrodes in special patterns they can create acoustics allowing specific manipulation of particles and fluids on the chip itself through the forces resulting from the acoustic waves. These patterns and their acoustic “force” fields look like this:

While it may sound very sciency, this research could actually be used for quite a lot of things. Non-invasive surgery would be the biggest benefactor from such a technology that allows doctors to target unhealthy tissue (like cancer cells) with acoustic jets to destroy them without ever having to touch the body itself. It could also be the next lab-on-chip, allowing you to delicately sort out blood samples to test them without needing a centrifuge in a proper lab or to isolate certain bacteria. The future is approaching faster than you think! You can read the article here and the paper here.

Table top X-ray accelerators

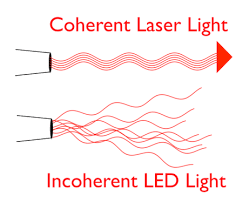

Researchers from the University of Liverpool have built a particle accelerator the size of a few micrometers that is able to generate intense coherent X-rays. A lot of big words and here is what they actually mean. Coherent light simply put means that waves within the light maintain a predictable fixed relationship to each other. This is a requirement for a lot of applications because otherwise the single waves within the light are just jumping around wildly and you can’t really measure anything reliably.

X-rays are particularly interesting because of their short wavelength that allows for all kinds of delicate applications. Shorter wavelengths mean you can measure smaller objects, i.e. you have higher resolution. And what makes them intense in that context is that there are a lot of particles/waves present. Now to get to the actual big breakthrough here: the researchers demonstrated a way to create these intense coherent X-rays with a very very small device. Normally you need huge particle accelerators that run for kilometers underground (e.g. think of CERN) to create this type of light.

The implication of this new type of device is that intense coherent X-rays are now a lot more accessible across research and industry, compressing a particle accelerator the size of a football stadium onto the size of a microchip. This will be especially relevant for doctors as it could make cancer diagnostics more accessible but also pharma companies have now an easier way to analyse protein structures with such a device in-house. There also might be the one or other application for semiconductor inspection in here to better analyse very small structures on chips.

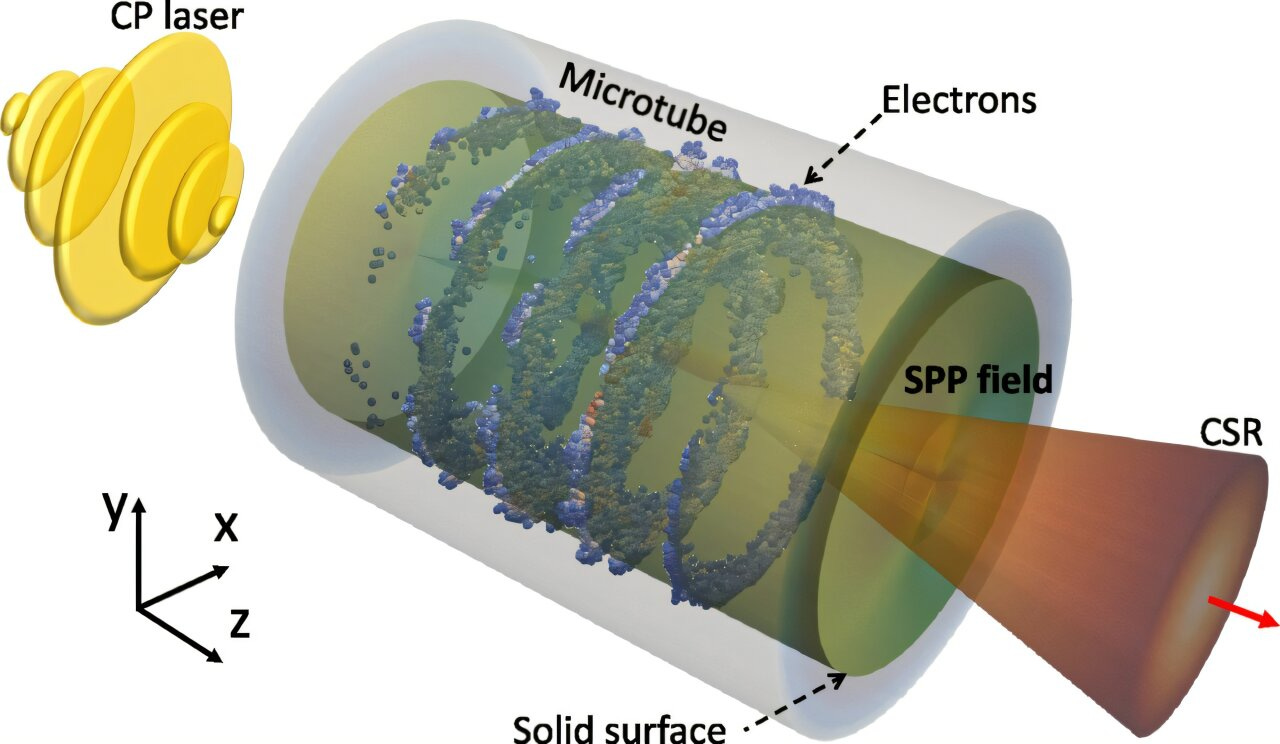

How does it work? Carbon nanotubes my friends - the wonder material that never ceases to surprise. Concretely the researchers have built a hollow tube out of carbon nanotubes and fire a “corkscrew” like laser through it. You can imagine the shape of the laser like a literal corkscrew, that screws around itself along its axis. The twisting laser light grabs onto electrons sitting inside around the tube of carbon nanotubes and spins them into a tight spiral. This spiral motion mimics what happens in these giant particle accelerators that accelerate particles in a huge (kilometer wide) donut, but in this case on a microscopic scale. At the end of the spiral the electrons are moving at near light speed emitting intense concentrated X-rays. If you want to learn more you can find the article here and the paper here.

🔬 Technology Frontiers

Supersonic commercial flight makes progress

Lockheed Martin and NASA successfully completed the first flight of the X-59 quiet supersonic aircraft, marking a major milestone in the quest to bring back supersonic commercial travel. The experimental jet took off from the Skunk Works facility in Palmdale, California, and flew for approximately one hour, reaching an altitude of 12,000 feet and a speed of 230 mph (370 km/h) before landing safely at NASA’s Armstrong Flight Research Center. Designed to reduce the window-rattling sonic boom to a gentle “thump,” the X-59 is the centerpiece of NASA’s Quesst mission, which aims to gather data that could lead regulators to lift the ban on commercial supersonic flight over land. This inaugural flight verified the aircraft’s airworthiness and initial handling qualities, paving the way for future tests where it will push the envelope to supersonic speeds and demonstrate its revolutionary quiet boom technology. You can find the article here.

Project Suncatcher

Space-based data centers made a bit of noise on Twitter/X in the last weeks and Google took this as an opportunity to officially join the conversation with its Project Suncatcher. This ambitious “moonshot” envisions a constellation of solar-powered satellites equipped with Google’s own TPU (tensor processing unit) accelerators instead of Nvidia GPUs. By launching these TPUs in form of data centers into a sun-synchronous Low Earth Orbit, Google aims to tap into near-constant (and technically free) solar energy. Initial radiation testing has already shown that their commercial TPU chips are surprisingly robust for space environments. The project is moving fast, with a prototype mission in partnership with Planet slated to launch two test satellites by early 2027 to validate the concept of machine learning in orbit. You can find the article here and the paper here.

Inflatable space stations from China

Chinese scientists have successfully concluded ground testing of a new inflatable space module. Developed by the Chinese Academy of Sciences (CAS), this reconfigurable structure is designed to launch in a tightly folded package and then inflate once in space, creating a stable, cylindrical workspace over two meters in diameter. The intention behind this is to build bigger structures in space you would need for space-based manufacturing without taking up too much space on the rocket at launch itself. Space factories are moving one step closer to reality. You can find the article here.

Nuclear reactors underground

Nuclear startup Deep Fission has announced a pilot site in Kansas for its mile-deep nuclear reactor. The company plans to lower a 15-megawatt micro-reactor into a 30-inch borehole a mile underground. The design uses the earth itself as a shield and containment vessel, dramatically slashing construction costs and safety risks. It’s definitely an interesting twist to a proven technology. Let’s see if this is the best way to build the future of nuclear. Maybe we just needed to dig a hole all along. You can find more details in the articles from Power Mag and IEEE Spectrum.

DNA data storage

Atlas Data Storage is debuting their “Eon 100” DNA data storage system. If you have no idea what DNA data storage is, I’ve written at length about it before here. The Eon 100 system is designed to replace massive magnetic tape libraries, as this compact appliance can hold 100 petabytes of data in a unit roughly the size of a mini-fridge. The system utilises an enzymatic process to encode data into stable DNA, ensuring information can be preserved for centuries without degradation, targeting the massive “cold storage” market of data storage - data that usually sits around untouched for years with very infrequent use. Unsurprisingly they do not mention their write speeds anywhere, which is the tricky part of DNA storage and the reason it has never taken off (yet). It doesn’t matter really if you can store hundreds of petabytes when it takes hours/days/years to actually write anything meaningful. You can find the article here.

💡 Articles & Ideas

Nailing Manufacturing Software GTM

Planet A Ventures has released an interesting deep dive into the unique challenges of selling software to the manufacturing industry. Despite the hype around Industry 4.0 10+ years ago (and now the hype around re-industrialisation), most factories are still stuck in an analog world. Why? Because the Go-To-Market for factories is fundamentally different than selling standard enterprise SaaS. Their guide distills some really valuable lessons for founders wanting to navigated this complex, risk-averse landscape. I’ll leave you some of the insights below but if you want to truly understand how to sell into manufacturing, then read the guide for yourself!

High production pressure, ever leaner staffing, and short-term targets leave little bandwidth for digital initiatives. Most factories simply lack the IT capacity to operationalise new software, creating a “do-it-for-me” adoption bias where tools that require internal ownership rarely stick.

After painful legacy experiences, manufacturers have learned to value accountability over capability. They pay for uptime, installation, or pay-per-output, not for another license that “enables possibilities”. They buy ownership of outcomes, not access to tools.

🤔 Odd Read of the Week

Characterising the perfect pasta with particle accelerators

Getting pasta to be al dente sounds very simple. Boil up some water, throw the pasta in, wait X minutes and you should be fine. Literally one ingredient (besides salt - I actually forgot about salt in the initial draft 🤣) and one process step of cooking. Well.. if you’re like me, then that can’t be further from the truth. Al dente is wizardry and needs a particle accelerator to be properly understood. And science agrees with me!

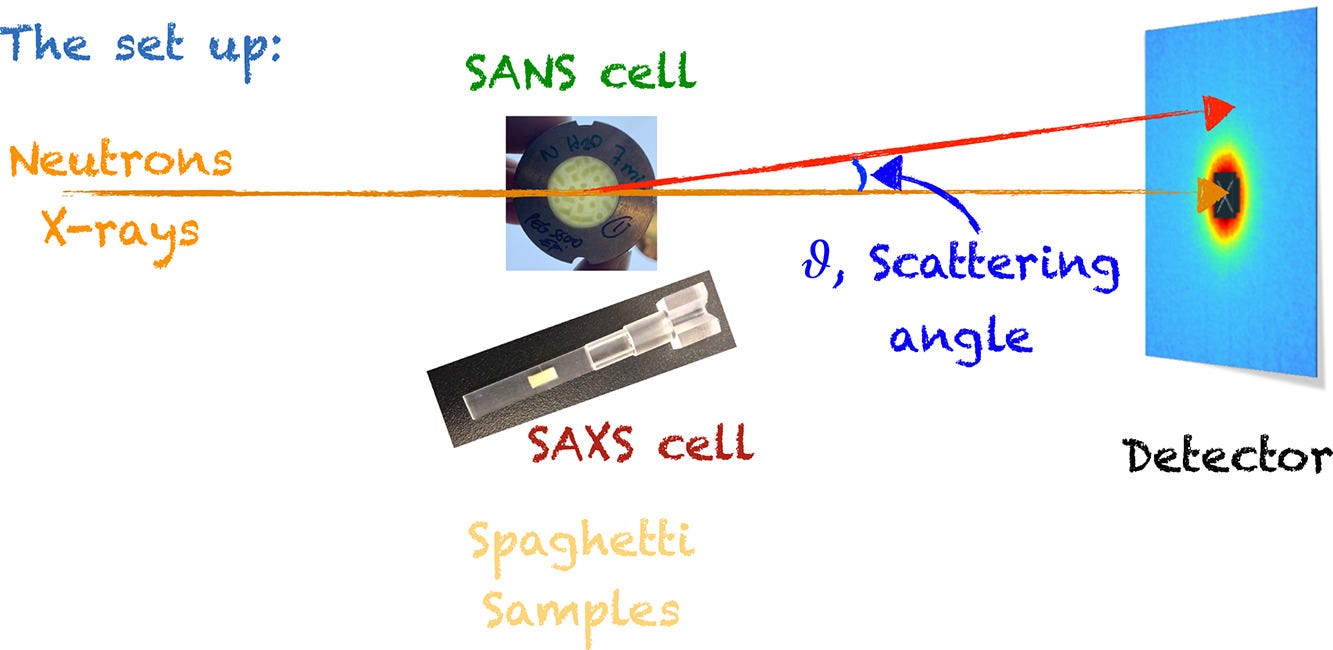

For that, researchers have actually used a particle accelerator (not a small one like in the science section above, but like an actual big donut underground just outside of Oxford) to throw coherent X-rays at pasta to truly understand what gives them the al dente structure in the cooking process on an atomic level. Turns out it is the gluten protein that holds the starch firmly in place. Depending on the cooking time this gluten scaffolding gets damaged and then pasta turns “mushy”. But there is also a relationship between these structures and the amount of salt you’re putting into the pot. Too much salt and that scaffolding gets damaged too. Turns out 7 grams of salt per litre of water is the optimum to keep the gluten happy. You can find the article here and the paper here.

📚 Further Goodreads

Why Not Everything is Automated in Manufacturing (Yet)

Deployment costs and “cost disease” are endemic in many areas of American industry, and manufacturing appears to be no exception. As a result of these deployment hurdles, we often see that companies deploy robots only because they are forced to, usually by labor shortages.

It’s also noteworthy that, as mentioned above, current industrial automation requires a large number of custom parts, which means that the best returns will only appear at the very largest manufacturing scales. Without a robust ecosystem for custom systems integration work and a broad depth of expertise in the market, integration costs will remain extremely high.

Who Actually Makes Money When Robots Work?

Seen this way, “progress in robotics” isn’t just better models. It’s the slow, painful process of redistributing uncertainty across these four layers until the whole stack makes economic sense. When a robot “gets better,” it’s usually because someone:

tightened the body bet (fewer physical failures)

improved the sensing bet (fewer blind spots)

moved brittle rules into a better planner or policy

changed the ops bet (smarter teleops)

Only after you internalize that does it make sense to talk about different categories of robotics companies. What distinguishes them isn’t just market, it’s where in this stack they choose to wrestle the world’s messiness to the ground.

Why Is Everyone’s Robot Folding Clothes?

We need to keep in mind what’s hard about these demonstrations. Human demonstrations are never perfect, nor are they perfectly consistent; for example, two human demonstrators will never grab the exact same part of an object with sub-millimeter precision. That’s potentially a problem if you want to screw a cover in place on top of a machine you’re building, but it’s not a problem at all for folding clothes, which is fairly forgiving.

This pushes people to keep going one step closer to their limits. This is piling on to more burnout. This is also why the WSJ reported that top researchers “said repeatedly that they work long hours by choice.” The best feel like they need to do this work or they’ll fall behind. It’s running one more experiment, running one more vibe test, reviewing one more colleague’s PR, reading one more paper, chasing down one more data contract. The to-do list is never empty.

The amount of context that you need to keep in your brain to perform well in many LM training contexts is ever increasing.

Do Orbital Data Centers Make Sense?

I think ODC’s are cool, and perhaps inevitable in the far future, but I don’t think they’ll be relevant to the nearer term future of AI in the next 10 or 20 years. The big deal breakers for me:

Engineering complexity of massive mega-structure deployments, maintenance, and lifetime costs. Cooling issues are usually what people balk at first, but I don’t think these are actually the barrier.

Upsets in model architecture and energy efficiency of computing platforms, which enable more on-edge AI computing.

Useful AGI is more likely to come from physical world interactions that involve continuous learning (from different model architectures than transformers)

As a civilization, if we can’t update things like permitting and regulatory oversight to make it faster and easier to build needed infrastructure, we’re all screwed anyway. AI is a geopolitical competitive front, so I expect there will be lots of land allocated to conventional data centers in the coming years.

The Decentralized Science Playbook

Another, though fleeting moat is to capture mindshare by doing *new* things. We think there’s way more potential for more livestreaming experiments, doing decentralized experiments on hormone maxing (testosterone and progesterone), betting on experimental outcomes, creating biobanks of consumer samples, and so much more. Events such as the Sperm Races show there’s at least 100k people that want to watch biology in action. While superficially, it’s a silly and irreverent event, what it shows is that there’s appetite to gamify the biological process. We can see DeSci communities pushing more on the gamification of biology to make it fun and bring in increasingly larger audiences.

Allocator’s Notebook: Union Square Ventures Funds I-III, 2004-2015

It’s not about the physical proximity, but rather about the mind share. They built the fund in NYC (and without any GPs on the ground in the Bay Area) to become one of the best in history, with the biggest outliers still coming from the Bay Area. They had some great success from the NYC startup ecosystem, but the biggest value drivers like Coinbase, Twitter, and Zynga all came from the Bay Area. Sometimes one differentiates with a killer blog and by being an outsider vs. being the Nth local firm (our Brazilian friends call this the Gringo effect).

Building fully autonomous construction robots would be very hard. In fact, to me, it seems to check off a full list of problems that make robotic automation difficult to impossible in the short term:

No pre-existing datasets: the large-scale vision language datasets online are all minimally useful for construction tasks

Lots of physical interaction: simulations like NVIDIA Omniverse or MuJoCo will generally not support these tasks well enough to be useful; if it is possible to make these simulations useful, they would need massive amounts of human effort, thus removing some of their advantages.

High precision requirements: buildings are built to specific tolerances, and the robots can’t start making mistakes!

Long horizon tasks: these precision requirements must be maintained over the completion of an entire structure, which is an incredibly long horizon task - one that takes expert humans days to weeks!

In other words, it may simply be every rich country’s destiny — whether it’s ruled by lawyers or by engineers — to transition from a “just build it” engineering-type culture to a fussy rules-and-procedures culture dominated by lawyers and economists.

This shift can be managed in better and worse ways, and it’s likely that America’s litigious behavior is a highly suboptimal approach. Dan Wang is very right about the woes of our “just sue them” culture. Yes, Chinese companies aren’t profitable, but at the end of the day, China will have houses and plentiful power plants and trains, and America…will simply not

In the same way that YC’s Request For Startups shifted from problem-driven ideas to consensus-seeking concepts, the formula for startup building reinforces the need to look like what’s fundable vs. building what is important. And this is increasingly true, not just in how companies get built, but how culture gets formed.

The most significant variable, though, appears to be latitude. For example, SAI [stratospheric aerosol injection] concentrated in polar regions would likely disrupt tropical monsoon systems. Releases concentrated in equatorial regions could affect the jet stream and disrupt atmospheric circulation patterns that conduct heat towards Earth’s poles.

“It isn’t just a matter of getting five teragrams of sulfur into the atmosphere. It matters where and when you do it,” says McNeill. These variabilities suggest that, if SAI takes place, it should be done in a centralized, coordinated fashion. Given geopolitical realities, however, the researchers say that is unlikely.

Diamond Blankets Will Keep Future Chips Cools

Rather than allowing heat to build up, what if we could spread it out right from the start, inside the chip?—diluting it like a cup of boiling water dropped into a swimming pool. Spreading out the heat would lower the temperature of the most critical devices and circuits and let the other time-tested cooling technologies work more efficiently. To do that, we’d have to introduce a highly thermally conductive material inside the IC, mere nanometers from the transistors, without messing up any of their very precise and sensitive properties. Enter an unexpected material—diamond.

The Future Of Propellantless Space Travel

For over a century, rocket propulsion has followed a simple principle; burn fuel, expel it backward, and Newton’s third law pushes you forward. Since Konstantin Tsiolkovsky first formulated the rocket equation in 1903, spacecraft have carried their propellant with them, limiting mission capabilities by the mass ratios. The more fuel you carry, the heavier your rocket becomes, requiring even more fuel to lift that fuel, in a vicious cycle that makes interstellar travel seem impossibly distant. But what if spacecraft didn’t need to carry propellant at all?