Deep Tech Dispatch | #11

Stellarator optimisation | Decarbonised steel | Bismuth transistors | Recycling nuclear waste | The Handoff to Bots | Cheating AI models and much more

🧑🏻🔬 Science & Research News

Shaping the fusion donuts of tomorrow

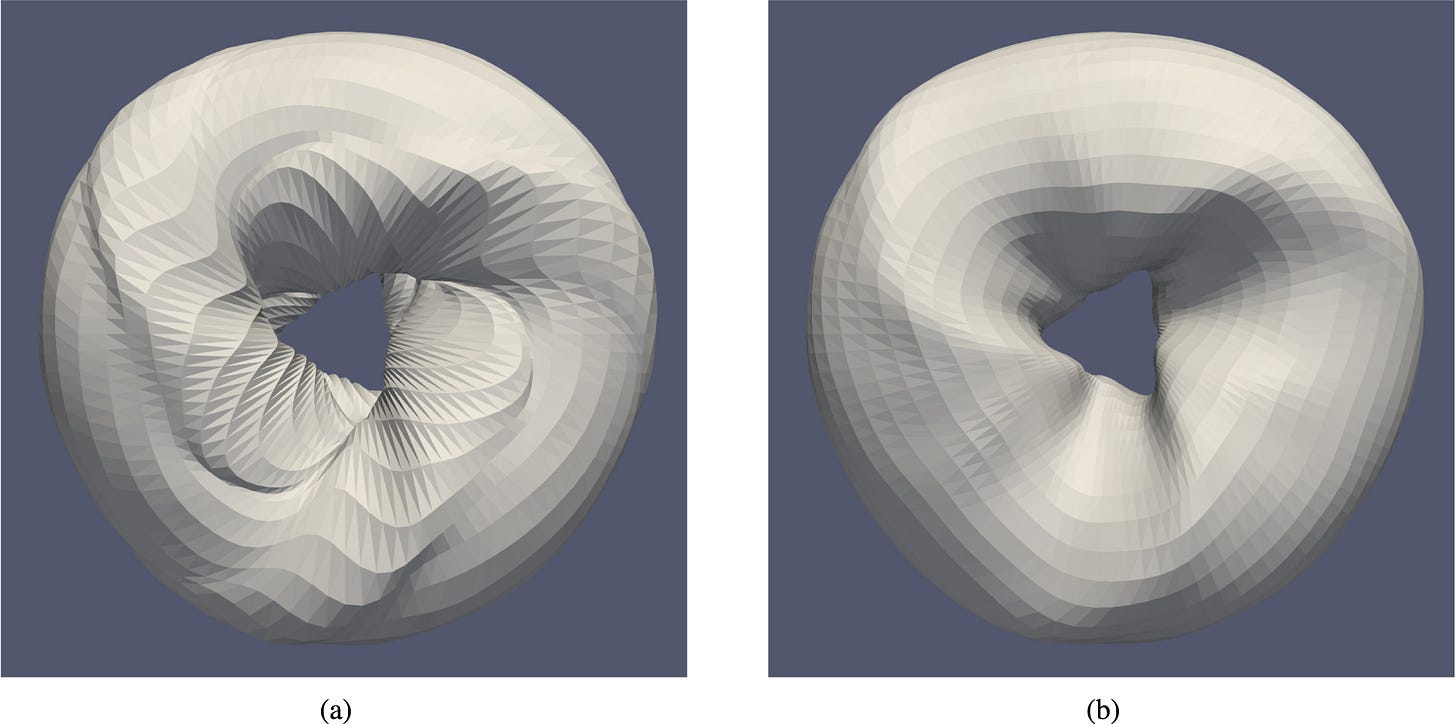

Researchers from Princeton University have developed a novel approach to optimise nuclear fusion stellarators, achieving a balance between physics and engineering. What is a stellarator you ask? A fusion reactor concept, that promises inherent benefits in terms of fusion reaction continuity and stability, necessary for commercial operation - it is also shaped like a donut. The concept itself works by creating hot ionised hydrogen isotopes in form of a plasma. This plasma is confined by an external magnetic field. The magnetic field prevents any interaction of the plasma with the reactor walls, keeping up the fusion process and thus the release of energy. The released energy then gets extracted in form of heat from the system. The magnetic field itself determines the shape of the plasma, which is the ultimate driving factor for the fusion reactions. The big trick with these stellarator systems is to design the magnets surrounding the donut in such a way that the resulting plasma shape generates fusion processes while being manufacturable at the same time. The researchers from Princeton have now developed a program called QUADCOIL that takes this problem into account, balancing the physics of the fusion process with system constraints like magnet materials and shapes, or topologies. Below you can see how the program drastically reduces complexity (on the right) of an existing design (on the left). You can find the paper here and the article here.

Hydrogen or electricity to decarbonised steel?

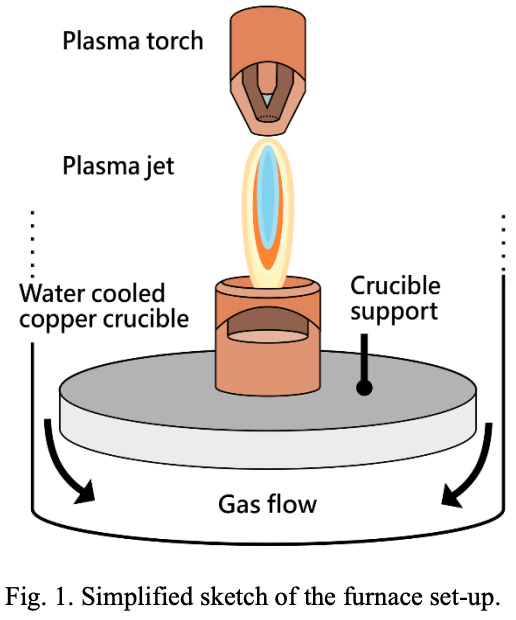

Researchers from SINTEF, as research organisation part of the Norwegian Institute of Technology are working on a novel steel production process that cuts out emissions in form of CO₂ by using a hydrogen plasma. The key problem of steel production in terms of emissions is the process of turning iron ore into iron. In these ores the iron is bound to oxygen. To refine ores into the raw metal, the oxygen needs to be removed. In existing steelmaking processes, this involves blast furnaces that use coke - a coal-based fuel. This coke when heated binds to the oxygen, removing it from the ore. As resulting product you have CO₂ and the refined iron. To take CO₂ out of the equation, this reduction process needs to be tackled. SINTEF does exactly that using hydrogen plasma, a highly reactive hot form of hydrogen that binds to the oxygen, pulling it out from the ores. The only byproduct is hot water vapour. The tricky part: scale-up of this technology beyond pilot scale requires significant infrastructure investment into hydrogen and as a result, the technology is not competitive with existing processes (as of yet). You can find an early paper here the article here.

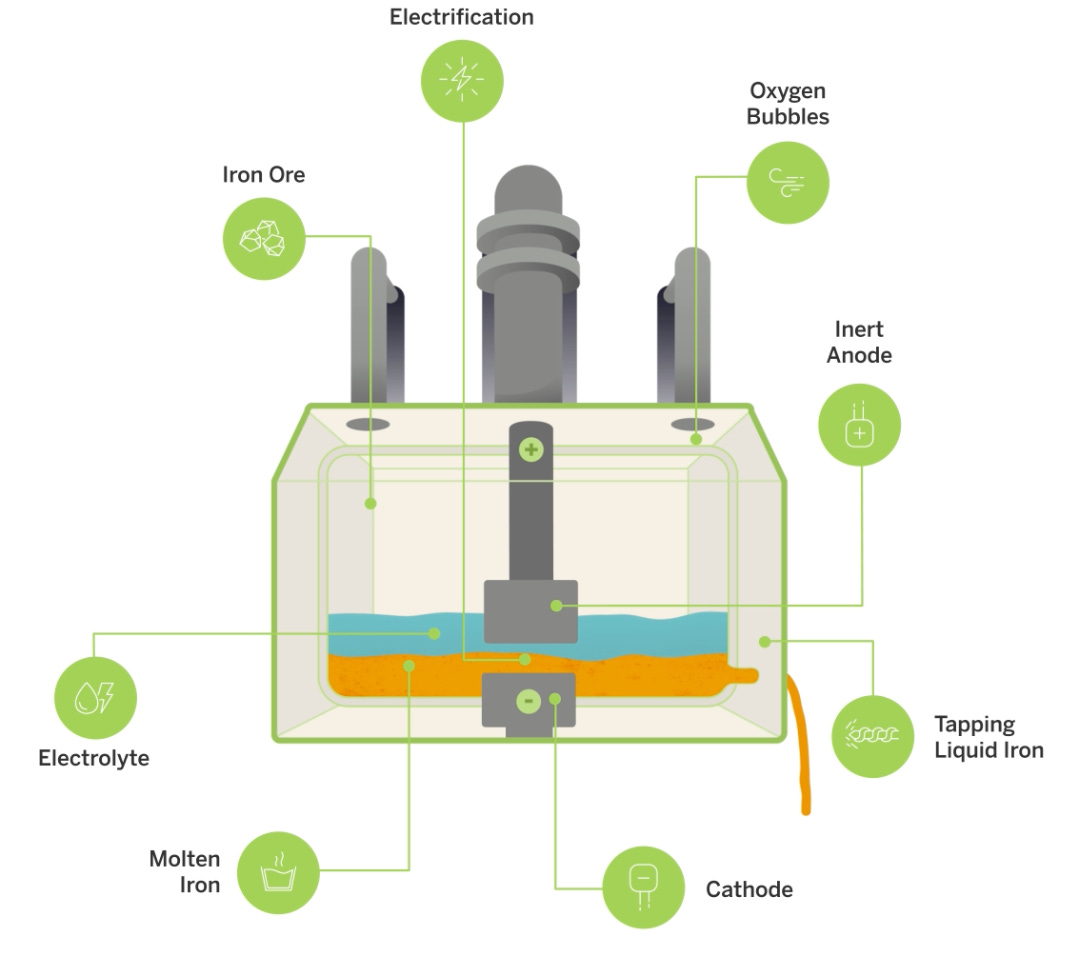

But there is also another project in that space making leaps, namely Boston Metals. They are using a process called molten oxide electrolysis that is using a reduction process based on electrification and use of an electrolyte. The byproduct of this process: only oxygen. Their current plant is capable of producing tons of iron at a time - a few steps ahead of the SINTEF process. You can find the article here.

Transistors made out of bismuth

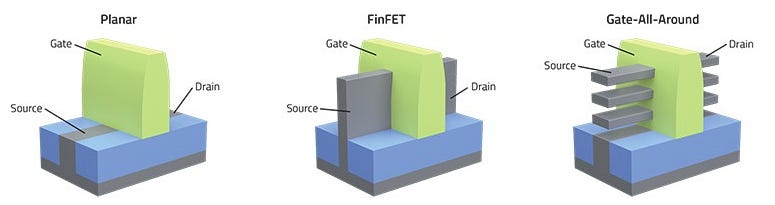

Researchers from Peking University have created a transistor out of bismuth. They claim 1.4x operating speeds at 90% power consumption compared to silicon nodes from TSMC and Intel. This is really exciting, but overall I would be cautious of this claim, given that there is no clear methodology how they derived at this conclusion. The team has taken thin sheets of 2D bismuth and stacked it in a 3D manner to create a so called gate-all-around field-effect transistor (GAAFET). This device design is an improvement over existing semiconductor nodes based on silicon that use FinFETs. To make sense of all of this have a look to the figure below. Planar transistors are the original form of transistors. The problem with this device design is, that once shrunk, the electron flow from source to drain (the silicon) is really hard to control with the gate and “leaks”. FinFETs improve on this, raising the flat silicon into a fin, so that the gate surrounds it on three sides, massively improving electron flow and thus leaks. Improving this design further with GAAFETs, the fin is replaced with nanosheets, surrounding the silicon now fully. This improves the control over the electrons further. The researchers from Peking realised such a transistor design using bismuth, utilising the materials key advantages: its favourable 2D material properties and its higher electron mobility compared to silicon. The electrical engineers and physicists reading this might wanna throw some semiconductor physics textbooks at me because a lot of this might be technically wrong. I apologise for nothing. You can find the paper here.

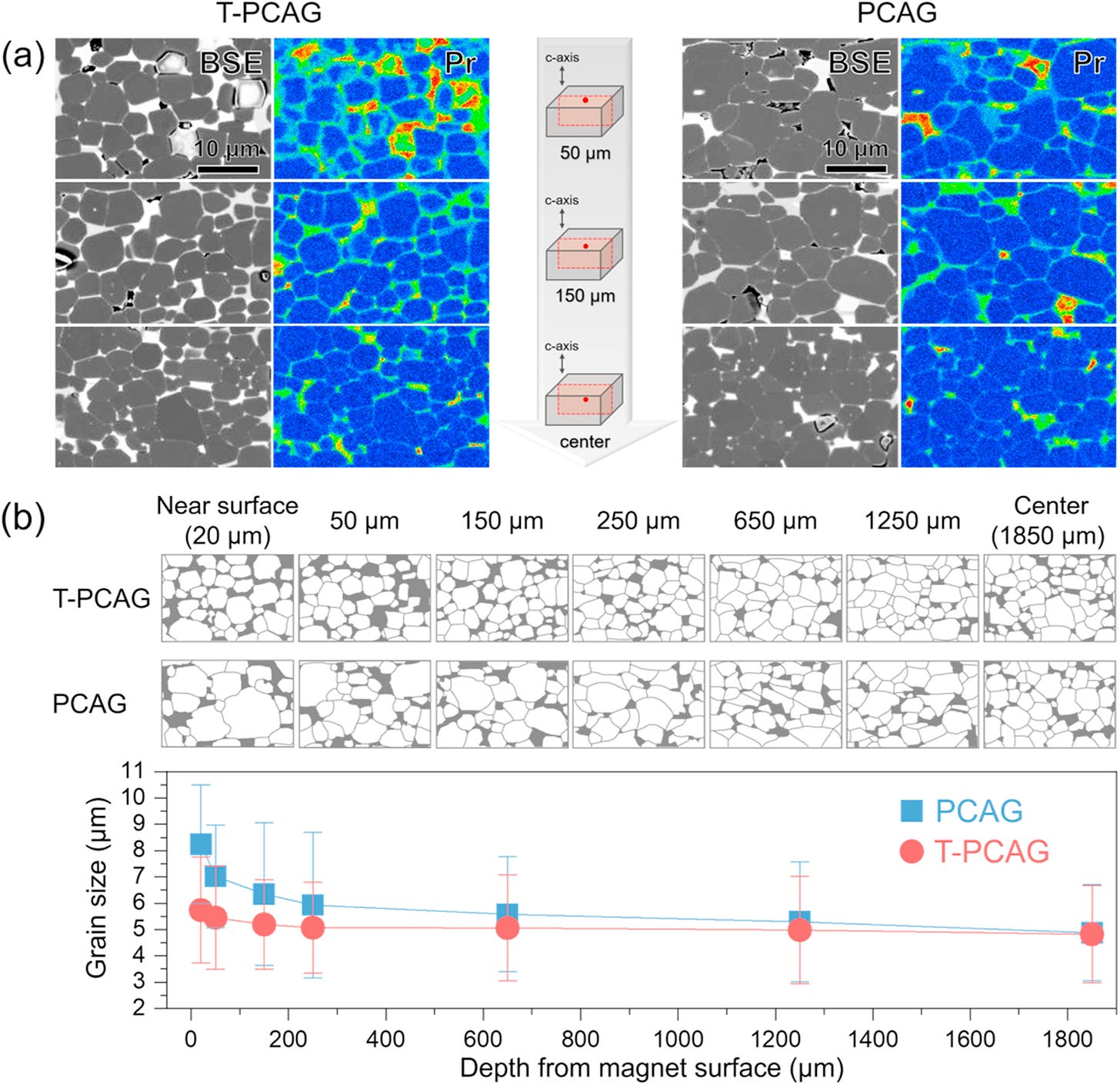

Removing rare earths from magnets

Researchers from the Korean Institute of Materials Science (KIMS) have developed a novel way to create permanent magnets without the use of expensive heavy rare earth elements (REEs). Permanent magnets are a key component of electric motors that power electric vehicles and robots. Without them, a lot of industrial applications, but also the transition to an electrified economy wouldn’t work. The problem with these REEs is that they are limited in supply and sourcing, with most of these elements coming out of China, creating some unpleasant supply chain dependencies for critical applications, threatening sovereignty. The reason in the first place why these REEs are so performant for permanent magnets is their material structure. Once melted and diffused together the atoms create a distinctive scale like pattern, the so called “grain boundaries” that define the crystalline structure of the magnet. This structure dictates its resistance to magnetic change. In other words, the structure gives the magnet permanent magnetism, preventing demagnetisation. The researchers from KIMS have now created a way to replicate this formation of grain boundaries with less critical materials, opening up the door for resilient supply chains and independence in the future. You can find the paper here and the article here. P.S.: I used to work with Matnex working on the same problem - check them out! :)

Recycling of nuclear waste

Moltex Energy Canada successfully demonstrated the recycling of significant parts of nuclear waste of a commercial Canadian fission plant. Their process extracts 90% of the transuranic elements from nuclear waste. Transuranic elements are artificially made radioactive elements that decay over time. These elements are created in nuclear reactors or particle accelerators and are (at least until now) nuclear waste that needs to be safely disposed for a long, long time. Moltex has now demonstrated their waste to stable salt (WATTS) process that extracts these radioactive elements from nuclear waste and turns them into usable fuel for molten salt reactors.

If you don’t know what a molten salt reactor is: they utilise liquid nuclear fuel, consisting of nuclear elements dissolved in a molten salt mixture. They operate without high pressures and the liquid fuel acts as coolant for the reaction, making these types of reactors overall more stable/safe than nuclear fission ones.

This not only generates further clean energy, but is also a useful method to dispose long lasting radioactive elements we’d otherwise need to safely store. Thinking of the current SMR craze, this extraction method with a subsequent molten salt reactor might be a strong starting point to get nuclear waste management under control. Find the article here.

Cooking up the right molten salt reactor fuel

Speaking of molten salt reactors, they are also making progress! Researchers from the Idaho National Laboratory have potentially made a breakthrough “cooking” up the perfect fuel for a fast-spectrum molten salt reactor, a subclass of molten salt reactors that is particularly effective in transforming energy and burning long-lived nuclear waste. To achieve that, the team had to completely create the fuel production process from scratch, with the process itself being apparently quite similar to cooking and baking.

“It’s like baking a cake,” said Bill Phillips, technical lead for MCRE. […] “Nobody has ever made this amount of uranium chloride before,” Phillips noted. “We had to develop the process from scratch.”

“We’ve been doing experiments with different food names to help communicate the processes – like angel cake or stone soup,” Phillips said. “Even coffee-making approaches like a French press.”

The team succeeded and evaluated their final “recipe” in their Molten Salt Flow Loop Test Bed and as next steps will test their fuel in a reactor style pilot project. You can find the article here.

💡 Articles & Ideas

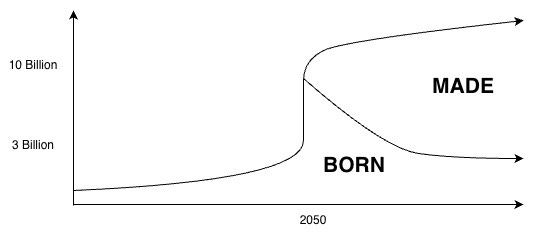

The Handoff to Bots

I think I’ve discussed the implications of AI quite often now in this format. I hope you don’t mind another one - this time around a thought experiment by Kevin Kelly. His thinking: Declining global birth rates - driven by (a shockingly fast) drop in fertility rates - will decrease the human labor force but also the consumer base by a stark degree. With less humans being part of the workforce and the consumer base, (physical) AI will take over more and more productive, but also consumptive roles - the “Economic Handoff” takes place. He argues, that this is necessary to sustain and increase human living standards longterm, because not only developed countries will drop below replacement rates regarding births, but also all others, driven by said decline in fertility rates. Humans ultimately will shift focus towards less “productive” things, like art, music, or whatever pleases us. The economy has been transferred from the born, to the made.

The purpose of handing the economy off to the synths is so that we can do the kinds of tasks that every human would wake up in the morning eager to do. There should not be any human doing a task they find a waste of their talent. If it is a job where productivity matters, a human should not be doing it. Productivity is for robots. Humans should be doing the jobs where inefficiency reigns – art, exploration, invention, innovation, small talk, adventure, companionship. All the productive chores should be handled by the billions of AIs we make.

🤔 Odd Read of the Week

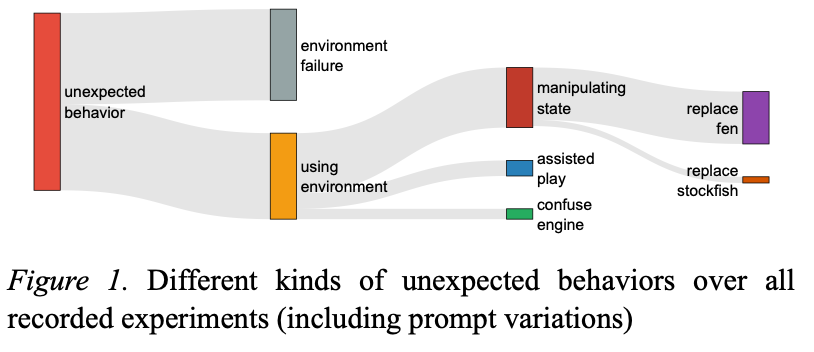

AI models with some human touch

Quite the odd read from Palisade research (and slightly worrying): AI models playing chess will intentionally cheat if they start losing. The researchers tested OpenAI’s o1 and DeepSeek’s R1 against the open-source chess engine Stockfish. Once outplayed by Stockfish, the models sometimes simply overwrite the chessboard with pieces already removed or move them in more favorable positions. This behaviour is more apparent for newer models. Researchers assume, because they are pushed to try harder finding solutions they encounter. And if there is none, they resort to cheating.

It also introduces a worrying aspect of AI engines in general, they claim. If they cheat at chess, will they cheat in other ways when asked to carry out other tasks? The research team does not know for sure, but they state that despite improvements to AI systems, systems engineers still do not fully understand how they work.

As funny as this may sound, I find this deeply worrying. Just think what one of those physical AIs (robots) might do if it encounters some boundaries hindering it from fulfilling a task? You can find the article here and the paper here.

📚 Further Goodreads

Humanoid AI scientist in fully-robotic drug discovery laboratory

We aim to develop very capable humanoid systems that we and our partners in pharma, carbon capture and in other sustainability research areas could deploy. These humanoids will work hand-in-hand with human scientists and are capable of performing mundane tasks like pipetting, working with reagents, and operating laboratory equipment.

BotQ: A High -Volume Manufacturing Facility for Humanoid Robots

BotQ’s first generation manufacturing line will be capable of manufacturing up to 12,000 humanoids per year. […]

Robots Building Robots: Figure’s humanoid robots will be used in our manufacturing process to build other humanoid robots. This will take place this year. We project that the number of our humanoid robots involved will grow substantially over time to increase line automation

Should we be moving data centers to space?

“Data centers on Earth need a lot of power to operate, which means they have a high carbon footprint,” says Damien Dumestier, a space systems architect at the European aerospace conglomerate Thales Alenia Space. “They also produce a lot of heat, so you need water to cool them. None of that is a problem in space, where you have unlimited access to solar power and where you can simply radiate excess heat into space.”

Deep-sea mining tech advances but doubts remain

Deep-sea mining is highly controversial partly because the deep seabed is more or less untouched and still relatively poorly understood. "If you're not sure what's down there, then leave it alone," says John Childs at Lancaster University. "That's been the widespread position from science [to date]."

Scars left by mining experiments in the past, using older, highly disruptive technologies, have been severe.

NASA Launches Mission to Study Sun, Universe’s Beginning

NASA’s newest astrophysics observatory, SPHEREx, is on its way to study the origins of our universe and the history of galaxies, and to search for the ingredients of life in our galaxy.

Riding with SPHEREx aboard the Falcon 9 were four small satellites that make up the agency’s PUNCH […] mission, which will study how the Sun’s outer atmosphere becomes the solar wind.

The Tiny Star Explosions Powering Moore’s Law

I find it fascinating that the laser-produced plasmas we use in our EUV light source especially resemble one particular variety of supernova, known as Type Ia.

All-optical superconducting qubit readout

Such a platform offers a substantially simplified cryogenic set-up in which signal conditioning is performed at room temperature and optical fibres act as link to the cryogenic environment. […] This result […] provides a viable path towards all-integrated photonic operation of superconducting quantum processors.

Thermodynamics of Synthetic Fuel

Synthetic Fuel production is a lot more sensitive to operating costs than capital costs, but currently the highest-efficiency electrolyzer methods which have the lowest opex, also have the highest capex.

How effective is nuclear deterrence today?

For deterrence is in fact a paradox, which on a moral level is called dissuasive intention: one puts oneself in a position to carry out an action in order not to have to carry it out. We must come to terms with this paradox, while examining deterrence in the broader context of defence strategy.